Most teams start this debate on raw material price per kilogram. That shortcut is how you end up paying for machining, rejects, and schedule slips later. The real decision is whether you need precision and finish at speed (often zinc) or light weight and heat tolerance at scale (often aluminium).

Below is how we compare them at SSOSS CAST, using shop floor results plus published alloy data and industry standards.

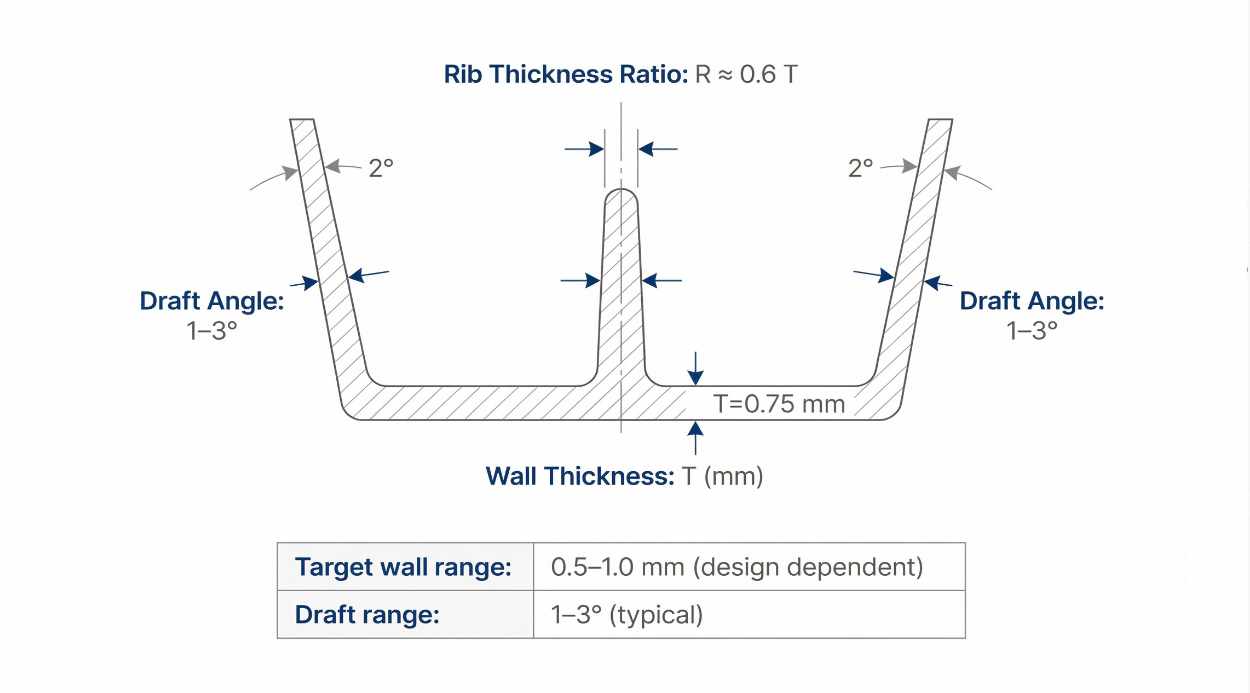

Which holds tighter tolerances and thinner walls in real production?

Zinc (especially Zinc #3 / Zamak 3) usually wins when your part needs very thin walls, sharp details, and tight as cast repeatability, so you can skip machining. Aluminium (such as ADC12) is excellent for larger parts and heat handling, but it more often needs CNC touch ups to hit precision fits, especially on thin wall features.

What the standards and data say

NADCA’s dimensional guidance explicitly notes that zinc can hold tighter tolerances depending on configuration and process controls, and it provides precision tolerance tables for die castings.

What we see in SSOSS CAST programs

In our Singapore production work, the tolerance story is rarely about a single number. It is about whether you can design to cast and lock in functional geometry without machining.

If your part has:

- Thin walls around 0.5 mm to 0.6 mm

- Fine ribs, small bosses, crisp lettering

- High cosmetic requirements before plating

Zinc is typically the easier path to stable repeatability because it fills thin sections well at lower temperatures, and it releases cleanly from the die.

Telecom connector housing example (40,000 units per year): We recommended Zinc #3 (Zamak 3) over aluminium ADC12 for a 0.6 mm wall requirement plus EMI shielding and a premium chrome finish. By switching to zinc, we removed three machining steps needed on the aluminium version. Rejects fell from 14% to under 2%, and polishing time before plating dropped about 50% because the zinc casting skin was cleaner.

Strength and stiffness: which material takes load better?

Quick reality check on strength values

Zinc #3 (Zamak 3) can be a strong and economical die cast zinc alloy. A Zamak 3 technical data sheet lists ultimate tensile strength around 41 ksi (283 MPa) and yield strength around 32 ksi (221 MPa). (Nathan Trotter) ADC12 aluminium data sheets commonly list ultimate tensile strength around 310 MPa and yield strength around 150 MPa (as cast, typical values). (Xometry择幢科技)

The practical difference

- If your part is small and highly stressed at contact points (latches, levers, brackets, hinges), zinc can deliver excellent local strength and wear resistance.

- If your part is large and load bearing where mass matters, aluminium often wins on strength to weight.

Density matters for cost and handling

- Zamak 3 density is about 6.6 g/cc. (Nathan Trotter)

- ADC12 density is about 2.74 g/cm³. (Xometry择幢科技)

So for the same geometry, zinc parts are heavier. That can be good for feel in hand (premium hardware) and bad for weight sensitive assemblies.

Rule we use: If the product team is fighting grams, aluminium is usually the first option. If the team is fighting deflection, wear, or fine mechanical features, zinc stays in the lead.

Heat and conductivity: when does aluminium clearly win?

If your part is doing real thermal work, aluminium is hard to beat.

Thermal conductivity comparison

An ADC12 datasheet lists thermal conductivity around 96 W/mK. (Xometry择幢科技) A Zamak 3 datasheet lists thermal conductivity as 65.3 BTU/ft/hr/°F. (Nathan Trotter)

So conductivity alone is not a simple zinc loses, aluminium wins story. The bigger divider in many projects is temperature capability and application environment.

Melting range and what it means for design risk

Zamak 3 melting range is listed at roughly 381°C to 387°C. (Nathan Trotter) ADC12 melting range is commonly listed around 516°C to 582°C. (Redstone Manufacturing®)

Aluminium’s higher temperature range usually makes it the safer choice for parts that see sustained heat, proximity to motors, power electronics, or hot air streams.

Simple guidance:

- Heat sinks, power housings, motor adjacent parts: aluminium is usually the default.

- EMI housings, precision shells, plated cosmetic electrical parts: zinc often gives better geometry control and finishing efficiency.

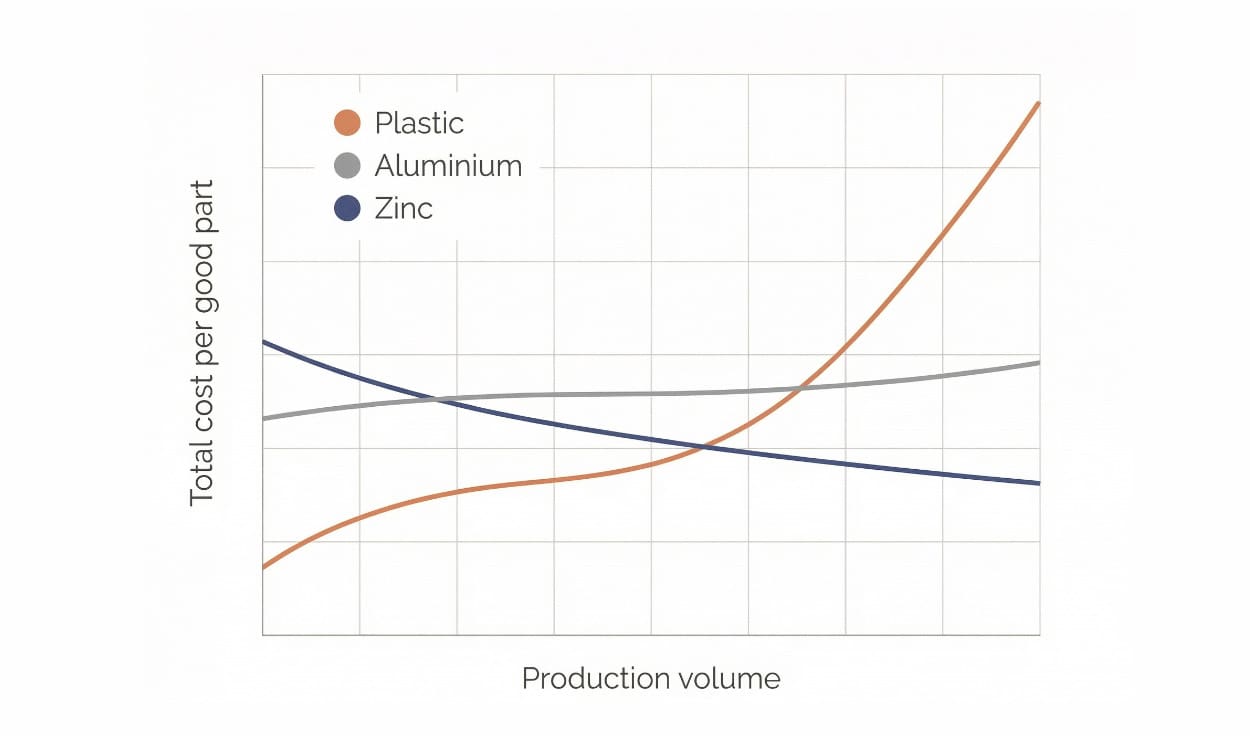

Total part cost: the hidden efficiency gap clients miss

Here is the misconception we correct the most.

Misconception

“Aluminium is always cheaper because the ingot price is lower.”

What actually drives total cost

- Cycle time and throughput NADCA explains that hot chamber die casting can run higher production rates because metal does not need to be transferred into a shot sleeve each cycle, while cold chamber production rates are typically lower. ([diecasting.org][4])

Zinc is commonly run hot chamber. Aluminium is commonly run cold chamber. That often translates into much faster zinc throughput for small to medium precision components.

- Machining avoidance If zinc lets you cast near final geometry, you can remove:

- CNC facing for flatness and sealing surfaces

- Post drilled holes and reamed fits

- Secondary trimming or deburring labor

This is where aluminium “cheap metal” can get expensive fast.

- Reject rate risk on thin walls Thin wall aluminium features are more sensitive to porosity and distortion. In our telecom connector housing program, the zinc switch reduced rejects from 14% to under 2% and removed three machining steps.

A comparison table you can use in sourcing meetings

| Cost lever | Zinc die casting (example: Zinc #3 / Zamak 3) | Aluminium die casting (example: ADC12) |

|---|---|---|

| Typical machine process | Often hot chamber | Often cold chamber ([diecasting.org][4]) |

| Throughput | Often higher for small precision parts | Often lower cycle efficiency for small parts |

| Secondary machining | Often avoidable on precision geometry | More likely on precision fits and thin wall features |

| Scrap and rework risk | Often lower on thin walls when tooling is correct | Often higher on very thin walls and cosmetic surfaces |

| Best value zone | High volume precision parts, plated cosmetics | Larger parts, thermal parts, weight sensitive parts |

Tooling life and maintenance: why zinc tools often last longer

This is where the temperature difference hits your budget.

Why the physics favors zinc tooling longevity

Lower melt and operating temperatures reduce thermal fatigue and soldering risk. That is one reason zinc programs often enjoy long die life.

SSOSS CAST experience marker

In our programs:

- Zinc tools often exceed 1,000,000 cycles, and we have tooling still running after about 5 years with managed maintenance.

- Aluminium tools commonly need major refurbishment or replacement around 100,000 to 150,000 cycles in demanding conditions due to thermal fatigue and soldering.

The takeaway for procurement: if you need long running high volume on a stable part design, zinc tooling ROI can be excellent.

Surface finish and plating: when zinc becomes the premium choice

If your part needs a “jewelry grade” finish, zinc often makes the job easier.

Why

- Zinc commonly produces a cleaner as cast skin that needs less polishing before plating.

- Zinc is widely used for decorative and functional plating systems.

This matches our telecom connector housing outcome, where polishing time before chrome plating dropped about 50%.

If you need plating support, see SSOSS CAST’s electroplating service page: SSOSS CAST electroplating services

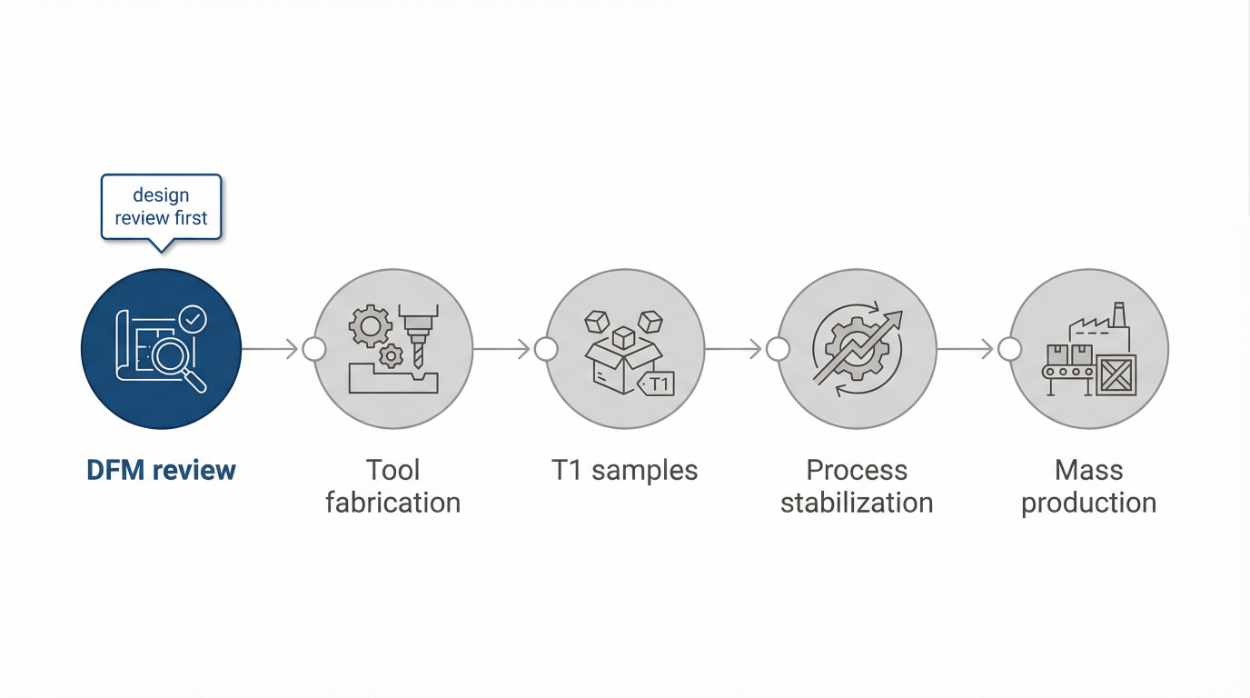

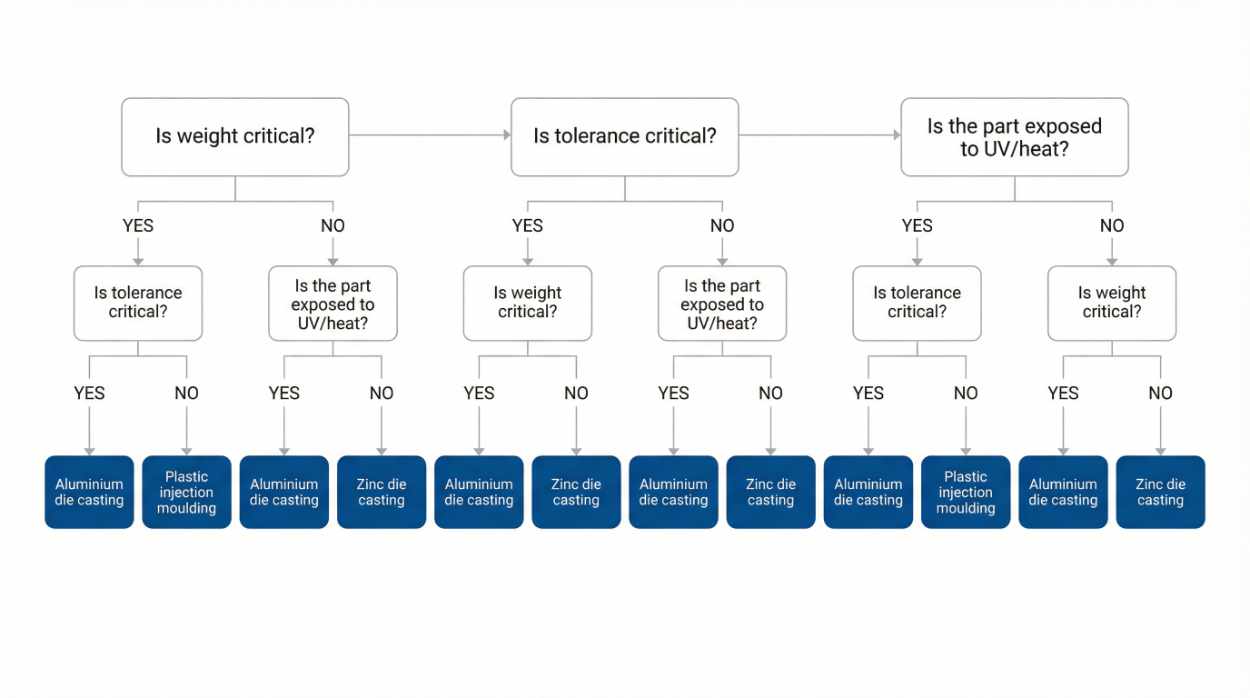

Decision framework: pick zinc or aluminium in 90 seconds

Use this checklist in your design review or RFQ brief.

Choose zinc die casting when

- You need thin walls around 0.5 mm to 0.8 mm and crisp detail

- You want to avoid machining and keep cost stable at volume

- You need premium plating and cosmetic consistency

- Your component is small to medium and weight is not the main constraint

- You need fast throughput and short lead time for high volume parts

Learn more about our zinc capability here: SSOSS CAST precision zinc die casting

Choose aluminium die casting when

- Your part is large or weight sensitive

- Your part sees higher operating temperatures

- You need strong thermal performance in real use

- You accept that precision fits may need CNC touch ups

Learn more about our aluminium capability here: SSOSS CAST precision aluminium die casting

FAQ

Is zinc always cheaper than aluminium in die casting?

No. Raw aluminium can be cheaper per kilogram, but total part cost often flips when zinc eliminates machining and reduces scrap on precision parts. Production rate differences between hot chamber and cold chamber processes also change cost. ([diecasting.org][4])

Which is better for EMI shielding housings?

Both can work, but zinc is commonly chosen for high precision housings where geometry control, conductivity, and plating quality matter. Zamak 3 electrical conductivity is listed around 27% IACS. (Nathan Trotter)

Can aluminium hit the same tolerances as zinc?

Sometimes, yes, but it depends heavily on geometry, process control, and whether you allow post machining. NADCA notes that tighter tolerances can be held for zinc depending on configuration and process methods.

What standard covers Zinc #3 / Zamak 3 composition and designation?

ASTM B86 includes Alloy 3 (Zamak 3) among its specified zinc and zinc-aluminium alloys. (ASTM International | ASTM)

Where can I get help choosing the alloy and process?

If you want us to sanity check your print and usage conditions, start with SSOSS CAST’s process overview and then reach out with your drawings. About die casting at SSOSS CAST Contact SSOSS CAST

Key references used

- NADCA die casting process FAQs on hot chamber vs cold chamber production rates. ([diecasting.org][4])

- NADCA product specification standards on tolerances.

- ASTM B86 specification page listing Alloy 3 (Zamak 3) designation. (ASTM International | ASTM)

- Zamak 3 alloy technical data sheet (melting range, density, strength, conductivity). (Nathan Trotter)

- ADC12 alloy data sheet (density, strength, thermal conductivity). (Xometry择幢科技)

[4]: https://www.diecasting.org/Web/Die_Casting/FAQ/Web/About/FAQ.aspx NADCA – Frequently Asked Questions